Slab Casting

There are two "1+1" 120 tons melting and casting production line and a "2+1" 90 ton melting and casting production line. Melting and holding furnace group design for the Otto Juncker company, the hydraulic tilting type gas heating furnace manufacturing Suzhou new light. The foundry machines all adopt the latest semi - continuous low level vertical shaft casting technology of WAGSTAFF in the United States. ABB is equipped with electromagnetic stirring, on-line hydrogen measurement and on-line slag measurement system. The online treatment of aluminum melt is based on French NOVELIS online degassing system and deep bed filtration system. Japan's Mitsui metal plate filtration and tubular filtration, the efficiency of degassing is 0.12ml/100g-AL, and the filtration efficiency is above 98% (10 m below impurities).

It can produce 1, 3, 5, 6, 8 series and other alloy ingots. The product specifications cover all the main specifications of the country, the smallest product is 520mm * 1000mm * 9150mm, the largest product is 640mm * 2410mm * 9150mm, the largest ingot weight is up to 37.5 tons.

Cleanliness measurement On-line hydrogen measurement by ABB-AISCAN

Cleanliness measurement On-line hydrogen measurement by ABB-AISCAN

Our use of France's Novelis Alpur three rotor three heaters online degassing system, capable of chlorine and argon, and the hydrogen removal efficiency can reach above 70%, deep drawing materials, aluminum billet, material tank hydrogen content can be controlled under 0.12ml/100gAl, the tank cover, pull ring material can be controlled under 0.14 ml/100gAl.

Novelis on-line degassing

slagging-off Machine STAS powder refining

Furnace refining equipment is rotary jet spray RFGI graphite rotor Canada STAS company design and production of refining equipment, high refining efficiency, degassing and slag refining effect, 40-50min can effectively remove most of the hydrogen in aluminum melt and slag, meet the high-end products in addition to hydrogen slag, aluminum and hydrogen content control in 0.30 the following ml/100g-Al.

The on-line filtration is the matching of plate filter and imported tube filter for Japan's Mitsui. The plate type filter for coarse filtration, the main role is to prolong the service life of the equipment behind the import filter, install 50PPI filter plate, can filter out more than 20 mu m impurities, filtration efficiency is 100%; the fine filter (tube type filter) can generally be impurity particles of more than 5 m by the vast majority of filter, filtration efficiency more than 95%.

Japanese Mitsui Corp tube filter system

Novelis deep bed filtration system

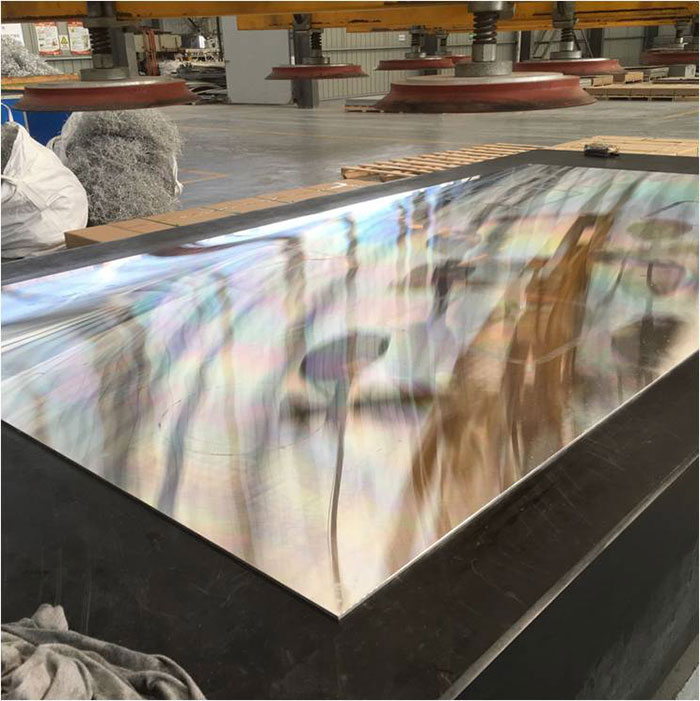

Casting system using Wagstaff casting system, strong stability, high safety coefficient, low level of LHCTM ingot casting process and the combination of the lubricating oil using only traditional direct condensation casting consumption of 3-5%, and the graphite cavity can be replaced, which greatly extend the life of crystal end. In the LHC production process of ingot, have minimal warpage and a small ingot shell, can obtain the milling surface quality and surface less yield can reach more than 97%.

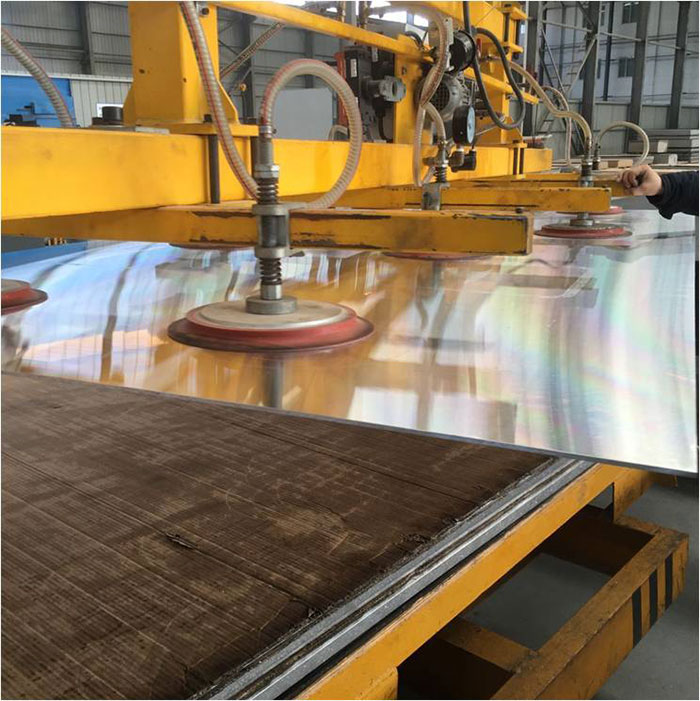

Wagtaff Aluminum slab casting system from United States

Wagtaff crystallizer specification:

640 * 1110-1310 adjustable, 640, 640 * 1650 fixed, 640 x 1340 fixed, 570 x 1810 fixed, 640 * 2110-2410 adjustable, 520 * 1350-1650 adjustable

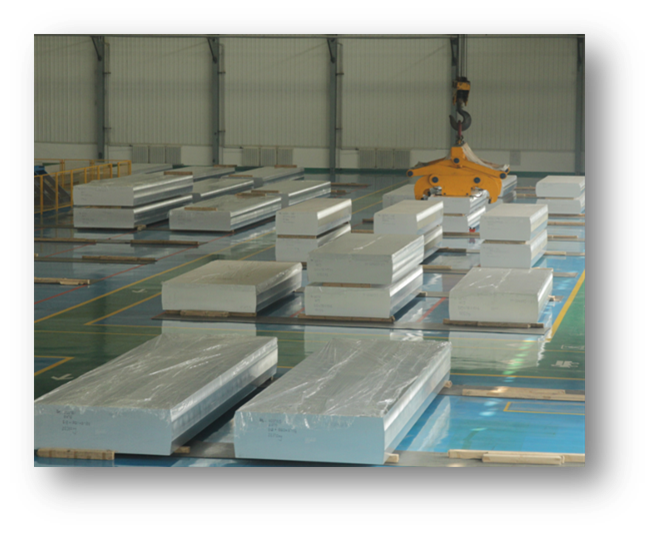

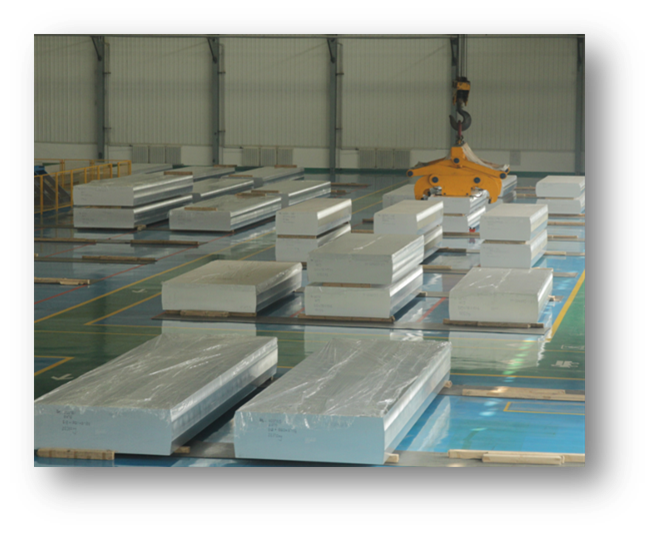

Aluminum slab Delivery

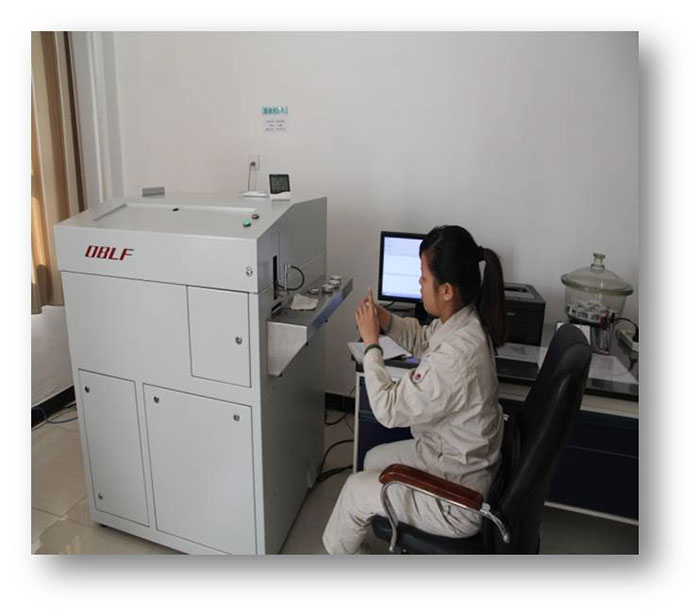

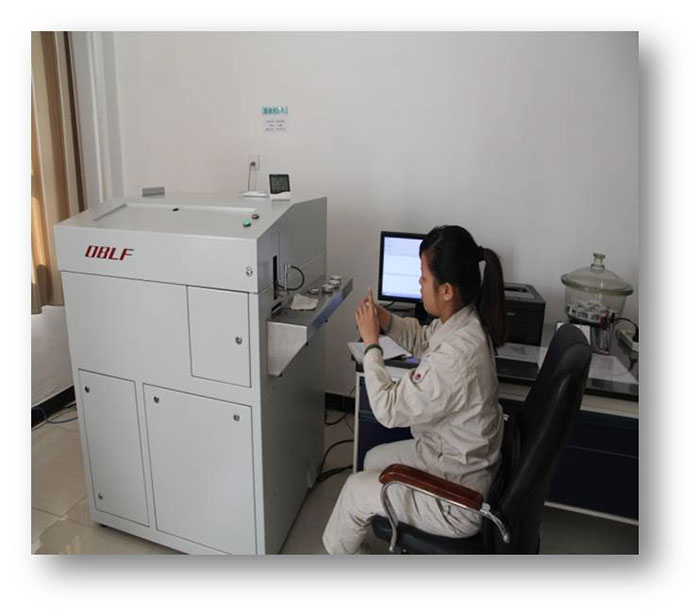

Analytical components of the German OBLF-QSN750-2 spectrometer

Stereoscopic analysis of low times

Macrograph test for Aluminum slab

Aluminum Slab NDT inspeciton

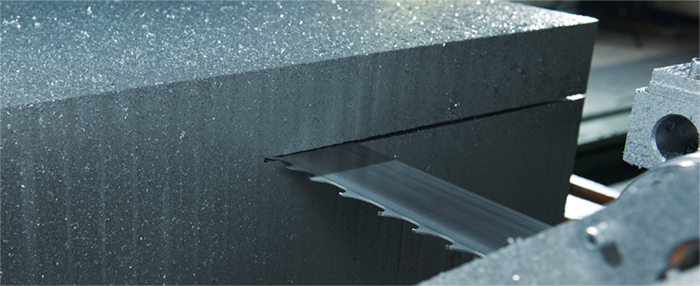

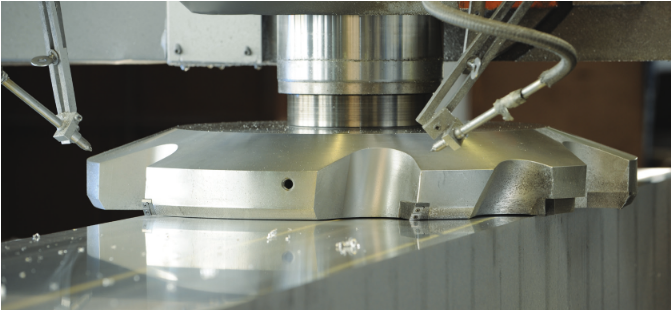

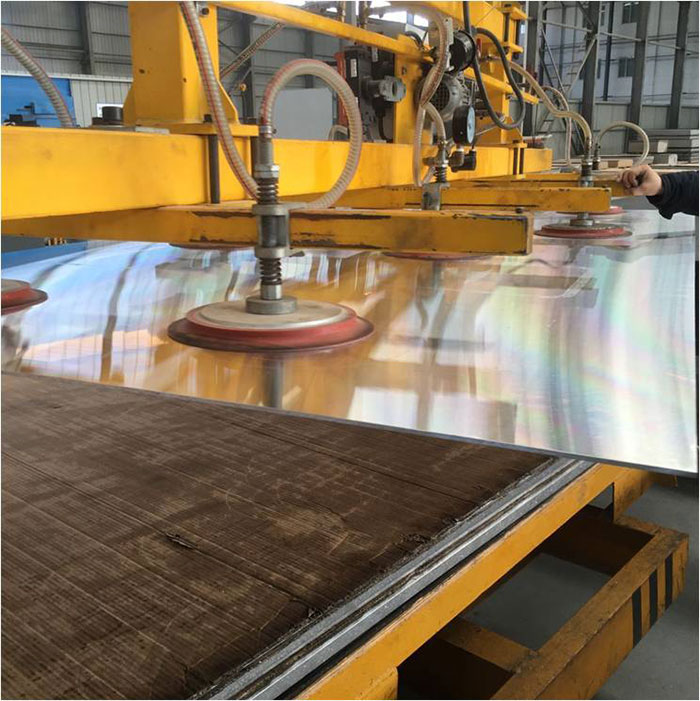

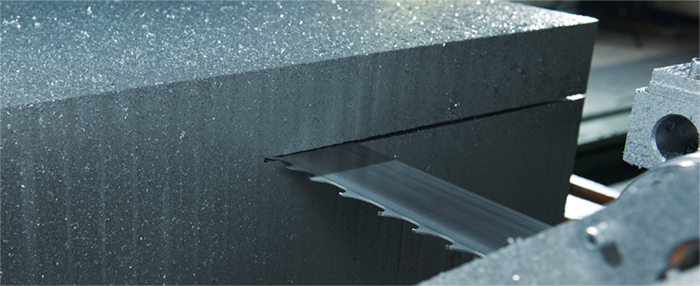

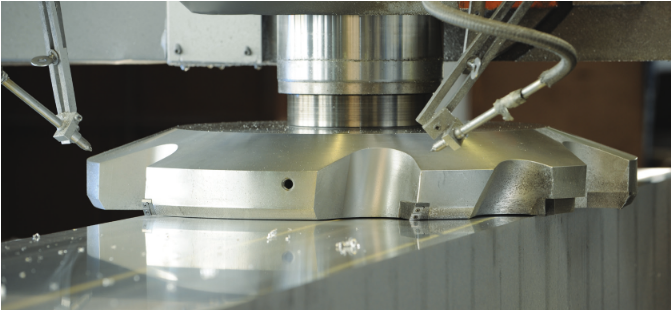

Sermas, a double headed sawing machine, which can be sawed at the same time at the same time, with a maximum speed of 10 blocks per hour. The milling machine is the most advanced model of Japanese Kobelco with high precision and high rigidity. The milling machine and sawing machine are arranged in a series way. After the aluminum slab is sawing the head and tail, it is transported directly to the #1 milling machine through the roller table to finish the milling on the top and side. After turning over automatically, the #2 milling machine will finish the milling of the other side, which greatly improves the efficiency of sawing and milling.

Sermas Sawing machine

SNK milling machine

Sawing and milling ingot specification range: width 960-2410mm, thickness 330-640mm, large surface milling precision up to less than 0.3mm.

Storage area of aluminum slab after sawing and milling

Sawing machine control room

Hot rolling project using SMS (1+4) type 2560mm hot rolling production line, hot pot material strip production capacity of more than 760kt/a, the maximum width of 2400mm strip, the thickness of 1.8mm. SIEMENS electrical configuration is advanced, equipped with a German IMS convex meter on line and closed loop control of thickness and plate type.

The hot rolling mill is equipped with hydraulic control system, CVCplus, work roll bending and multi zone cooling system, temperature control system, equipped with light shear, heavy shear, trimming machine, coiler, waste transportation system, flue gas purification system, etc.。

4 flat ingot pusher heating furnace, by Otto Junker (OttoJunker) design, manufacturing Suzhou xinchangguang, the maximum thickness of 620mm ingot. The maximum installed capacity of each furnace is 860 tons, which can hold 25 34T flat ingot, and 4 stoves have heating and heating function, which can meet the needs of heating and heating technology.

Through special heat treatment, the material internal stress is extremely low, the processing size stability is super, the supply size range is extremely flexible, the mechanical performance is very excellent!��The available thickness range is 10~395mm. It can supply all dimensions of the flat ingot type range according to the requirement.

Precision sawing machine

Precision sawing machine

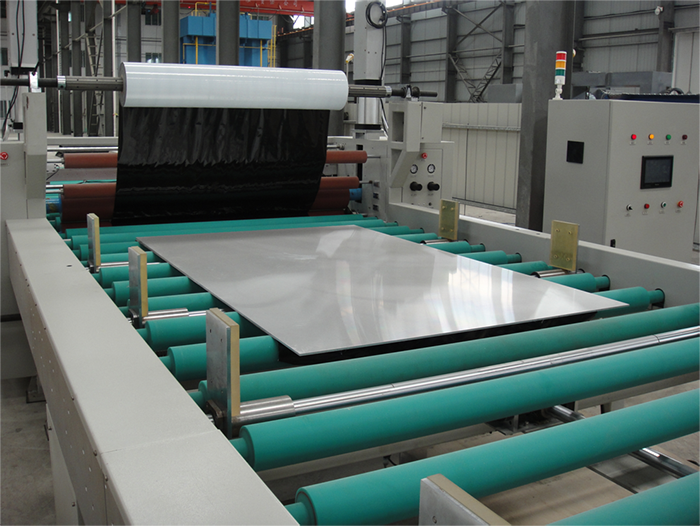

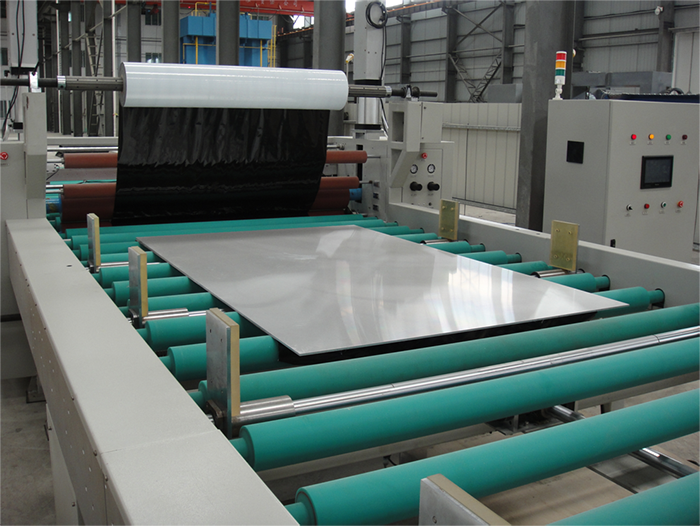

Special surface treatment

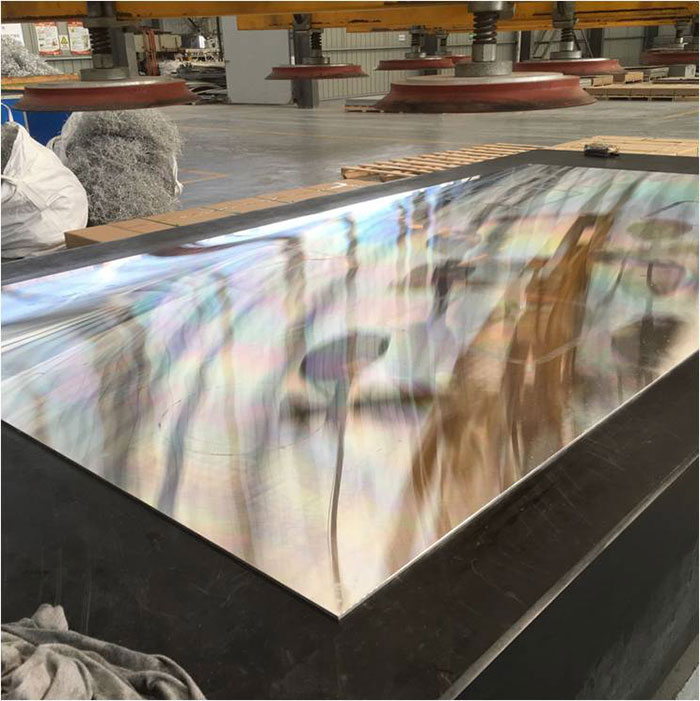

Surface precision milling machine

Both sides film protection

Perfect flat surface

Solid wooden pallet packing

Solid wooden pallet packing