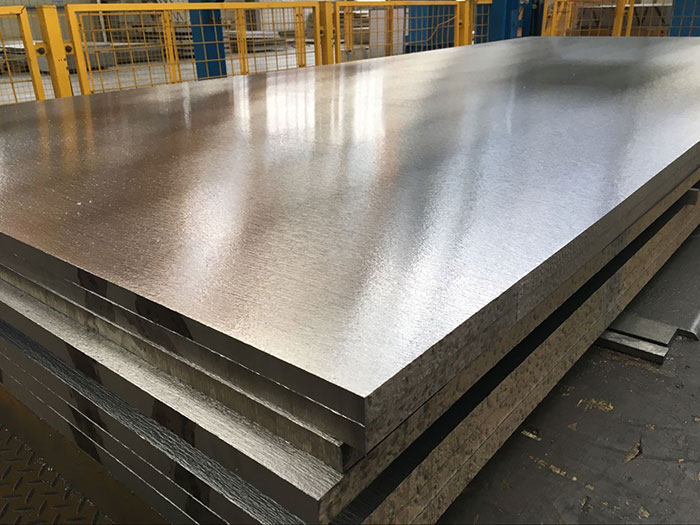

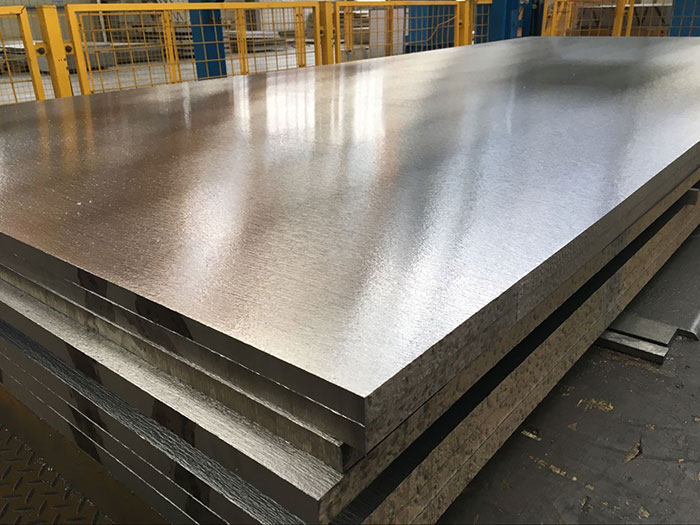

Precision cast aluminum plate have a precision machined surface for superior flatness, flat within . 015'', and +/- . 005'' thickness tolerance, and are protected with PVC plastic on both sides.

precision cast aluminum plate typically has a surface finish of 25 RMS or better.

applications include, but are not limited to, Computer & Electronics, Pharmaceuticals, Machining fixtures, Drill jigs, Index tables, Semi-Conductor, Automotive Molds

Characteristics of

precision cast aluminum plate

1. Homogenised and stress relieved

2. Precision milled, roughness Ra0.4um, foiled on both sides

3.High strength, good corrosion resistance and oxidation resistance.

4. Isotropic homogeneity, higher dimension stability.

5. Anti-magnetic, anti-radiation.

6. Fine surface milling as requirement. Good surface quality, the finished product can be double side filmed.

Material features: Casting, homogeneity

Machinability: Very good

Weldability: Very good

Anodic oxidation properties: Good, not decorative

Polishability: Very good

Corrosion resistance: Very good

WEDN machining: good

Thickness ranges and sizes:

Plate thickness between 5mm---100mm

Other dimension available on request

Tolerance:

Surface: Precision milled

Surface roughness Ra <=0.4um

Thickness tolerance: +/-0.05mm

Flatness: 6---12mm thickness<=0.30mm

>12-100mm thickness<=0.12mm

Tolerance in width: -0+10mm

Tolerance in length: -0+15mm