7075 T6 precision machining mold aluminum alloy plate is aluminum, zinc, magnesium alloy, one of the most powerful alloys in commercial use, common corrosion resistance and mechanical properties. 7075-T6 has good plasticity after solution treatment, and the heat treatment strengthening effect is particularly good, below 150 degrees High strength, and has a particularly good low temperature strength, poor weldability, stress corrosion cracking tendency, two-stage aging can improve the anti-scc performance.

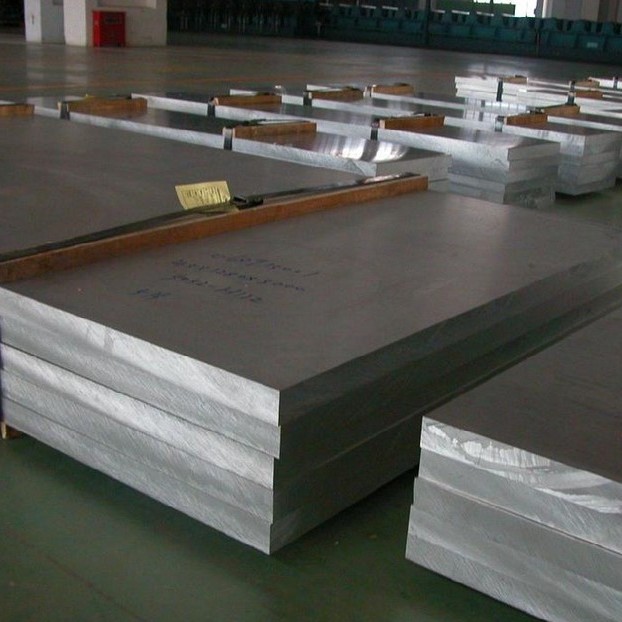

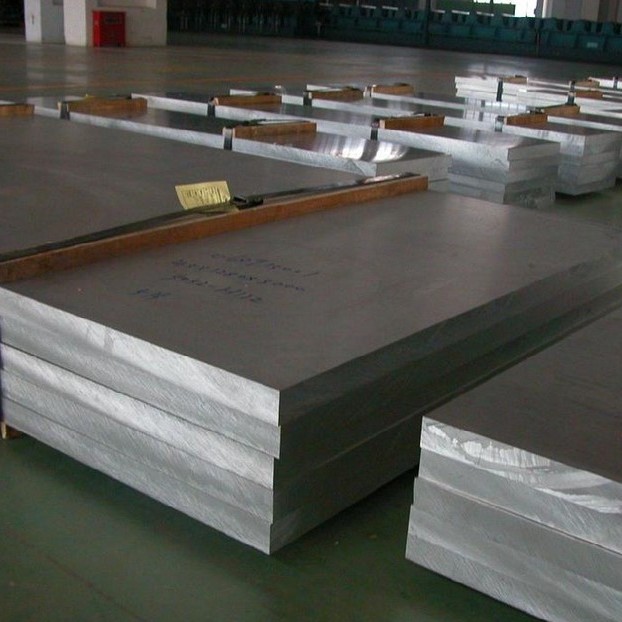

7075 T6 precision machining aluminum plate

7075 T6 precision machining aluminum plate’s chemical composition: silicon si; 0.4 iron Fe; 0.5 copper CU; 1.2-2.0 manganese Mn; 0.3 magnesium Mg; 2.1-2.9 chromium Cr; 0.18-0.28 zinc Zn; 5.1-6.1 titanium Ti;

The main alloying element of 7075 is zinc, which has high strength, good mechanical properties and anode reaction.

7075 T6 cast mould aluminum alloy plate is mainly used in the manufacture of aircraft structures and other high-stress structural parts that require high strength and corrosion resistance, such as upper and lower wing walls. Plate, purlin, etc.. Good solution after solution treatment, good heat treatment strengthening effect, good strength below 150 degrees, and particularly good low temperature strength, poor welding performance, stress corrosion cracking tendency. Also widely used in mold Processing, mechanical equipment, fixtures, etc.