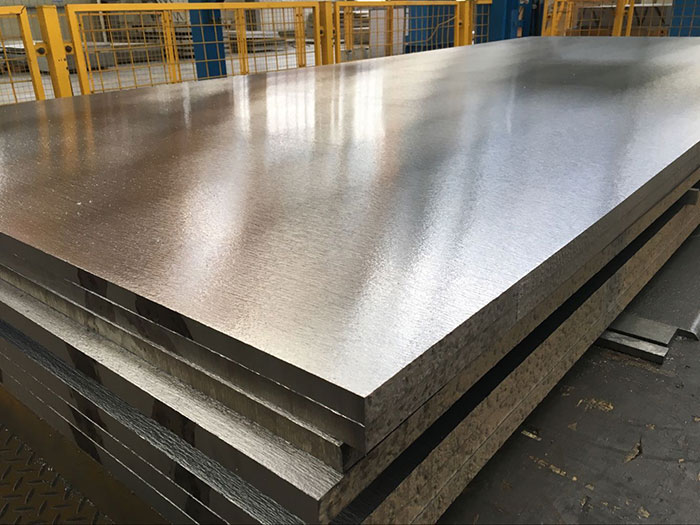

5A83 precision aluminum alloy plate is improved on the basis of European standard DIN EN 573-3/3.3547, meeting the requirements of food grade materials, widely used in IT, semiconductor, medical, electronic instruments, optical and communication vehicles and platforms, precision machinery , reference boards, panels, engine manufacturing and fixture manufacturing, vehicle engineering, shipbuilding, aerospace fixtures, bicycle accessories, valve bodies, tube formwork, tableware molds, food grade packaging, blow/blister molds, formwork, marine work components, General tools and more. Due to the addition of a small amount of rare earth elements and B and C, the heat conduction, heat dissipation, high temperature and corrosion resistance are improved; the dimensional accuracy and processing stability of the sheet are at an international advanced level.

5A83 is a new national grade aluminum alloy independently developed by Chalcoaluminum, which has better comprehensive performance than traditional 5083 alloy.

The strict control of impurities, alkali metal elements and low melting point elements of

5A83 precision aluminum plate improves the corrosion resistance and creep resistance of the alloy. Both sides of the plate are milled to produce ultra-fine surface, and the dimensional tolerance standard is the world leader. Inspection, double-sided film protection, strength exceeds similar products in Europe, high thickness coverage (≥4.5mm), tensile strength of homogeneous alloy: 270 ~ 300MPa; yield strength: 110 ~ 130MPa; elongation after break: ≥ 12.0%; Brinell hardness: ≥70HBW, milling surface roughness Ra≤0.4μm.

1. By continuously optimizing the production process, the flatness of the aluminum plate is greatly improved. The 10-100mm thick aluminum plate is guaranteed to be within 0.127mm per square meter, and the thickness tolerance is ±0.05mm.

2. Through the exclusive heat treatment technology, the residual stress inside the alloy plate is greatly reduced!

3. Each alloy plate undergoes strict surface and internal inspection to ensure that high-quality aluminum alloy plates are put into the market!

Contribute to cost savings for customers while reducing residual stress and improving surface quality!

A large number of used in structural materials, semiconductor manufacturing equipment, liquid crystal manufacturing equipment, solar panel manufacturing equipment, industrial robots, medical equipment, office automation equipment, optical instruments, various molds, fixtures, etc.!